What To Avoid When Choosing Your New Garden Timber Building Supplier

To help when choosing your new garden timber building supplier, we have compiled a basic list of what we consider to be essential to avoid in the construction of your new timber building. Sometimes the price of your new garden shed tells you a lot more about how it is made and what it's made from. Is a cheap price always the best buy? Our Hobbyshop & Proshop garden timber buildings are constructed so you don’t have to worry about any of the issues shown below.

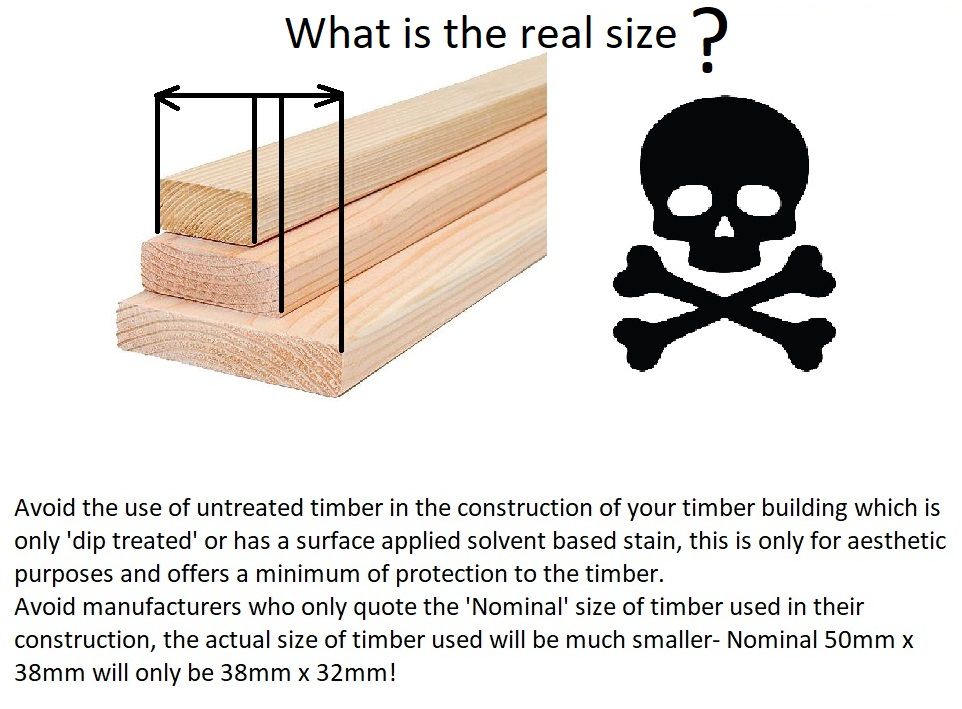

Construction Timber Size & Treatment

Avoid companies that quote only the nominal size of timber used (before the timber is machined smooth) in their timber building specification as, although they are not lying to you, they are being a little deceitful. If you are not used to how timber sizes are quoted within the timber industry you need to be told what the 'actual' timber size is or you will be tricked into thinking your building is to be made with timber which is bigger than it really is. As a guide, if you are quoted the framework timber to be used as a nominal size of 50mm x 38mm the actual finished size of the timber will be 38mm x 32mm so you can see that the timber quoted is considerably smaller than what you think you are getting. Shiplap cladding is also quoted by many manufacturers at its nominal size so, shiplap that is quoted with a nominal thickness of 16mm actually finishes at 12mm. We quote you the actual size of timber and cladding used or we will quote you both nominal and actual so you are fully aware of the size of timber used in the construction of your building.

- Our Hobbyshop garden sheds use a full to size 45mm x 45mm C16 structural graded Tanalised timbers throughout their construction.

- Our Proshop range of timber workshops use a minimum size Tanalised Timber for the framework, floor bearers and roof purlins of 38mmx 63mm .

Avoid the use of undersized wall framework at spacings which allow the external cladding to warp and twist. Choose a building which has a framework of a minimum of 45mm x 45mm giving a cross-sectional area of a minimum 2025mm² (the cross-sectional area is simply the 2 measurements multiplied together) and a maximum spacing of the wall uprights at 600mm (this will help to stop the external cladding warping). We use full to size 45mm x 45mm Tanalised timbers for our Hobbyshop walls at max. 600mm centres, and a minimum size of 38mm x 63mm Tanalised timbers for our Proshop walls at max. 400mm centres.

Avoid the use of undersized and non-Tanalised floor bearer timber framework at spacings which allow the floor deck to bounce, ‘sag’ and decay over time due to moisture and stale air under the building floor. Choose a building which has floor timbers of a minimum 45mm x 45mm giving a cross-sectional area of a minimum 2025mm² and maximum spacings apart of the floor bearers of no more 300mm, make sure the floor bearers are Tanalised. Using floor bearers that are not Tanalised (high pressure treated) will greatly reduce the life span of your building. We use full to size 45mm x 45mm Tanalised timbers for our Hobbyshop floor bearers at max. 300mm centres, and a minimum size of 38mm x 63mm Tanalised timbers for our Proshop walls at max. 400mm centres.

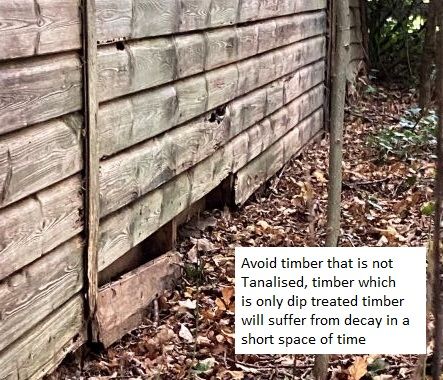

Avoid the use of untreated timber in the construction of a timber building which is then only 'dip treated' or 'solvent based timber treated' as this does not offer anywhere near the longevity and anti-timber rot quality of timber which is high pressure treated with Tanalith E (Tanalised timber). Tanalised timber is expected to have a minimum of a 10yr service life, this will be extended with regular timber treatment applications, untreated timber in damp conditions can start to rot in under 2 years.

- Our Hobbyshop & Proshop buildings use fully Tanalised timbers for their wall framework, floor bearers & roof purlins, All external cladding & timber work is fully Tanalised.

TANALISED E pressure treated timber is impregnated with Тanalith® E, waterborne product based on copper triazole technology. Copper is derived from recycled sources and triazoles are organic biodegradable biocides, commonly used to protect many of the food crops we eat. TANALISED E pressure treated timber is usually specified for both in and out of ground contact applications where there is a medium to high risk of decay or insect attack.

• An established and proven alternative to traditional chromated/copper/arsenate (CCA) treated timber.

• Effective long-term protection against fungal and insect attack.

• Proven performance, widely used and accepted worldwide.

• Appealing natural green colour with excellent colour durability, blending perfectly with nature.

• Impregnated using vacuum pressure technology.

• Conforms to new European Standards and individual countries' national requirements.

• Ideal for general construction, fencing, garden and leisure timber applications.

External Cladding

Avoid the use of shiplap cladding which exceeds the nominal width of 125mm (finished size after machining to 123mm) , shiplap cladding wider than 125mm has a higher tendency to ‘cup’ and split. Many timber building manufacturers use 150mm cladding as it is quicker to manufacture the building. The thickness of the shiplap cladding is less important as long as it is a minimum of 12mm. We use Tanalised T&G shiplap with a nominal size of 125mm x 16mm with a finished actual size on average of 120mm x 14mm with a 13mm tongue and a 14mm grove on our Hobbyshop & Proshop range timber buildings, this size of tonge and groove allows for the natural swelling and shrinking of the cladding.

All treated shiplap cladding will shrink as the material dries, if the building is facing direct sunlight the shiplap with shrink to a greater degree. Shiplap with a rebate or tongue depth of less than 13mm will have a tendency to separate if the building is in direct sun. Most timber building companies use a rebate or tongue depth of circa ≤10mm to increase the amount of area a board covers and so will use less boards to make the building. With this reduced rebate or tongue depth, if the boards shrink excessively, the boards may (and very often do) shrink beyond the rebate or tongue and groove and such create a gap on the external cladding. We only use shiplap with a 14mm tongue and groove milled especially for our Hobbyshop & Proshop timber buildings.

As timber is a natural product, it is susceptible to shrinking, bowing, splitting and knots becoming loose. To successfully manage these common issues, it is important to manufacture a timber building using quality materials and 'best practice' construction methods. All our timber buildings use Tanalised timber framework and quality Redwood saw falling grade cladding.

Failure to apply 'best practice' when manufacturing a timber building will very quickly show areas where the new building begins to 'fail'.

Dimensional Timber shrinkage

In addition to being hygroscopic (gaining or losing moisture from the surrounding air), wood is also anisotropic. What this means is that wood has different properties depending on the direction or orientation of the grain—it’s not the same in all directions—and one of the areas where this property is most clearly seen is in dimensional shrinkage.

As opposed to a simple sponge or other isotropic material, wood (anisotropic) does not shrink in a perfectly uniform manner, and understanding this will help to avoid some pitfalls in preventing many shrinkage-related defects which may not crop up until months (or even years) after the wood product is finished.

A basic measurement of shrinkage—expressed as a percentage—is the amount that the wood shrinks when going from its green to kiln dried state. In other words, since wood in its green state is at its largest dimension, and kiln dried represents its driest (and therefore smallest) volume, green to kiln dried is a measurement of the maximum possible percentage of shrinkage; this is referred to as the wood’s volumetric shrinkage.

Volumetric shrinkage tells how much a wood species will shrink, but it doesn’t indicate the direction of the shrinkage. The two primary planes or surfaces of wood where shrinkage takes place are across the radial plane, and across the tangential plane, corresponding to radial shrinkage, and tangential shrinkage; these two values, when combined, should roughly add up to the volumetric shrinkage.

The amount a piece of wood will shrink lengthwise, called longitudinal shrinkage, is so small—typically about 0.1% to 0.2%—that it is usually inconsequential to the volumetric shrinkage.

Radial shrinkage in solid wood can vary from less than 2% for some of the most stable wood species, upwards to around 8% for the least stable species; most woods fall in the range of about 3% to 5% radial shrinkage. Tangential shrinkage can vary from about 3% up to around 12%; most woods fall in the range of about 6% to 10% tangential shrinkage. (Accordingly, volumetric shrinkage is typically within the range of 9% to 15% for most wood species.)

HAYMAC SHIPLAP

Our tongue and groove shiplap cladding is specifically milled for us with an extra long tongue and groove. This allows for the naturally high Tangential & Radial shrinkage associated with redwood Tanalised cladding. The Tangential shrinkage on average is between 6% & 12%(12% on the thinner tongue) and the Radial shrinkage is on average approx. 2%. This gives an approx. average shrinkage on its thickness (Radial) of circa .3mm and approx. average shrinkage on its board width (Tangential) of circa 7.5mm. This Radial shrinkage means the tongue could shrink by about 2mm with the groove shrinking by about 0.8mm, these measurements do vary between boards of differing moisture content.

Make Sure The Roof & Floor Are Built Correctly

Avoid any manufacturer that does not install a roof truss on your apex roof building where the building roof length exceeds 1.5m or 5ft (this is the length run and not the apex or gable width). The building roof will ‘sag’ over time if unsupported at a length greater than 1.8m or 6ft and cause the roofing felt to fail. Roof trusses should be installed on every building where the roof length exceeds 1.8m or 6ft; so, a 8ft long building should have one truss, a 12ft long building should also have one roof truss and a 13ft long building should have 2 trusses (evenly spaced out about 4ft 3" apart) and so on. Buildings up to 1.8m or 6ft in roof length do not need a truss if the roof timbers are of an adequate cross-sectional area and adequate spacings apart. Pent roof buildings should have roof timbers of a minimum 45mm x 95mm at 300mm centres and the span should not exceed 3.0m of 10ft.

We install a roof truss on all our Hobbyshops and Proshops which have a length of roof over 1.8m (6ft). Our roof trusses are constructed using full to size 45mm x 95mm structural C16 GRADE Tanalised timber as a minimum.

Avoid the use of undersized roofing timbers installed at spacings which allow the roof to ‘sag’. Choose a building which has roof timbers of a minimum 45mm x 45mm giving a cross sectional area of a minimum 2025mm² (the cross-sectional area is simply the 2 measurements multiplied together) and maximum spacings apart of 300mm. We use full to size 45mm x 45mm Tanalised timbers for our Hobbyshop roof purlins at max. 400mm centres, and a minimum size of 38mm x 63mm Tanalised timbers for our Proshop roof purlins at max. 300mm centres.

Avoid the use of budget grade roofing felt, choose a roofing felt which is Polyester based with a mineral felt coating (with a minimum weight of 2kg per metre/20kg per 10m role). Polyester based roofing felt has a high resistance to tearing, roofing felt tears are the most common form of roof failure on all timber buildings. You can test this yourself by asking to see a sample of the roofing felt used, put a crease in the sample by bending the felt over onto itself and if you can easily tear it along the crease or even just tear it from the edge of the felt the roofing felt should be avoided. We use Polyester based green mineral coated roofing felt at 2kg/m on our Hobbyshop timber buildings and a higher quality Ultrapol SBS Polyester Mineral Shed Roofing Felt at 2.5kg/m on our Proshop timber builidngs.

Avoid the use of T&G (tongue & grooved) boarding on the roof and floor. T&G boarding will shrink as the timber dries out creating gaps in the floor which allows dirt to build up in joints which is not a structural issue but does make keeping your new building floor clean a little more problematic. A much more important issue is the use of this boarding as a roof deck, once your roofing felt has been tacked to the roof deck the roofing felt is fixed to each individual board and when the roof boards shrink (independently of each other, with some shrinking more than others) the roofing felt has to move with the board it has been tacked onto and will subsequently tear where the felt tack is or even worse may crack along a board joint. The use of moisture resistant solid sheet boarding (OSB3) negates this problem. We use 11mm OSB 3 moisture resistant sheet boarding for the roof deck on both our Hobbyshop and Proshop buildings.

Base Frames & Concrete Slabs

Avoid any manufacturer that suggests their shed floor can sit directly onto a patio or concrete slab larger than the building floor dimensions or directly onto your grass or garden. All timber (treated or not) will absorb water, cut end timber which exposes the timber end grain will absorb even more water which will penetrate through to the building floor. All timber buildings should have their floor raised above any possible standing water or ground moisture with the installation of a sub-frame base with at least 18mm of free airflow beneath the building. Your new building floor should be installed on a raised sub-frame base if installed on a patio or concrete slab larger than the size of the building floor. Our sub-frame bases for patio installed buildings come with 18mm non-porous Polyurethane blocks fitted as standard. Buildings installed over grass or soil should be installed on a raised sub-frame installed with support posts concreted into the ground. We will always advise you of the correct base for your new timber building, we would never advise you place your shed floor directly onto a concrete slab that is bigger than your building floor or installed directly onto grass or soil without a suitable sub-frame base.

Make Sure Your New Shed is Tall Enough

Avoid buying a timber building which has a low internal height at both the eaves and apex, many manufacturers only quote the external height at the apex as this gives the maximum overall height of the building. You will go into your new building after installation in your garden and find that head height clearances or useable wall space may not be what you require, remember if you see 6ft at apex externally the internal height could be a low as 5ft 7” or 1.70m after deducting the floor and roof thicknesses. We consider the minimum heights required for a useable apex roof timber building to be internally 1.97m at the eaves and 2.19m at the apex with pent roof sheds being slightly different with the low side internally being approx. 1.945m and the high side being approx. 2.165m. Both our Apex Hobbyshop and Apex Proshop buildings have internal heights of 1.97m at the eaves and 2.19m at the apex .

Make Sure Your New Shed is Watertight

Avoid buying a timber building where the door has not been manufactured to provide the best method of keeping the rain out of your new building, the door should have its cladding extended down over the floor to provide as good as possible rain seal (or a door cill provided), the same should be apparent at the top of the door to the door frame. Door stops should also be installed to avoid water penetration from the door shuts. Timber building doors are always problematic with water penetration so best efforts by the manufacturer should always be important in the door design. You will never stop heavy driven rain penetrating an 'opening out' timber garden building door but best efforts in construction seriously do help.

Avoid buying a timber building where the windows are not adequately made weather proof with the use of a full frame window with window cill. The windows on both our Hobbyshop and Proshop buildings have a full frame with window cill and external window head cover fillets with 3mm glass.

Planning Permission & Building Regulations Compliance

- Please make sure your proposed new timber building can be installed in your garden without needing planning permission or building regulation compliance, ask your proposed supplier to explain what you can and cannot have if you are in any doubt. If you install a garden building which fails permitted development guidelines or fails to be compliant with building regulations you will have to remove your new garden building.

- Our timber buildings are built to be compliant with the permitted development rights which allow you to install a timber building in your garden as long as the building size and location installed fit in with what is allowed.

- We will always offer you guidance before you purchase.

- Please click on the Permitted Development button above to find out more.